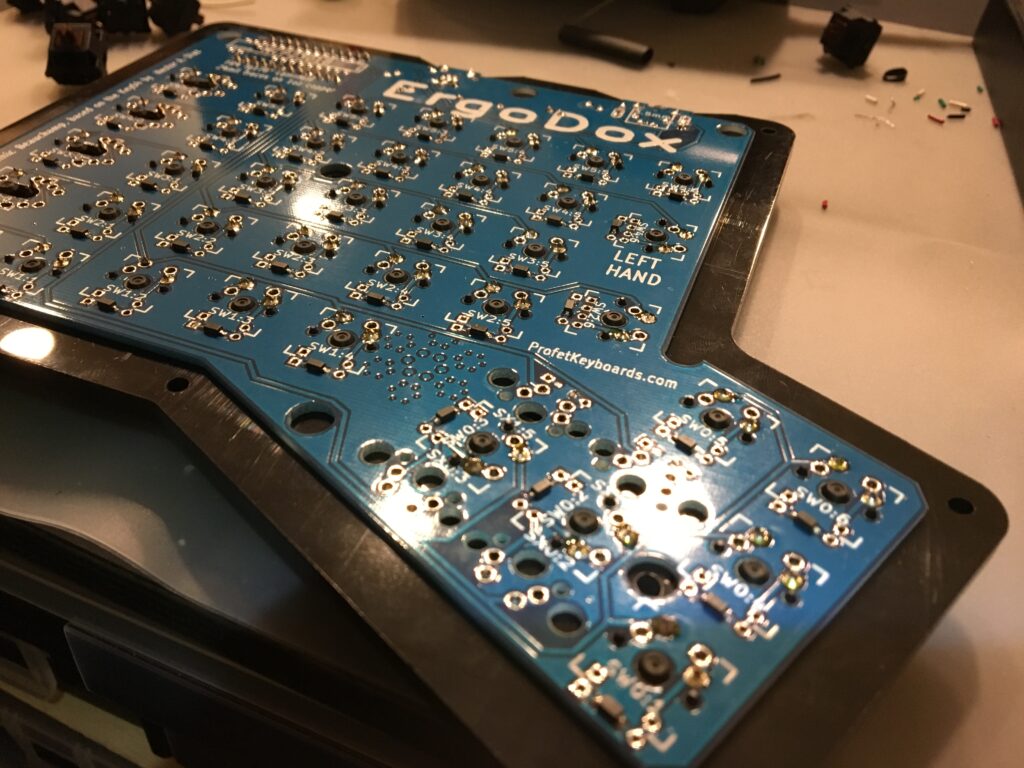

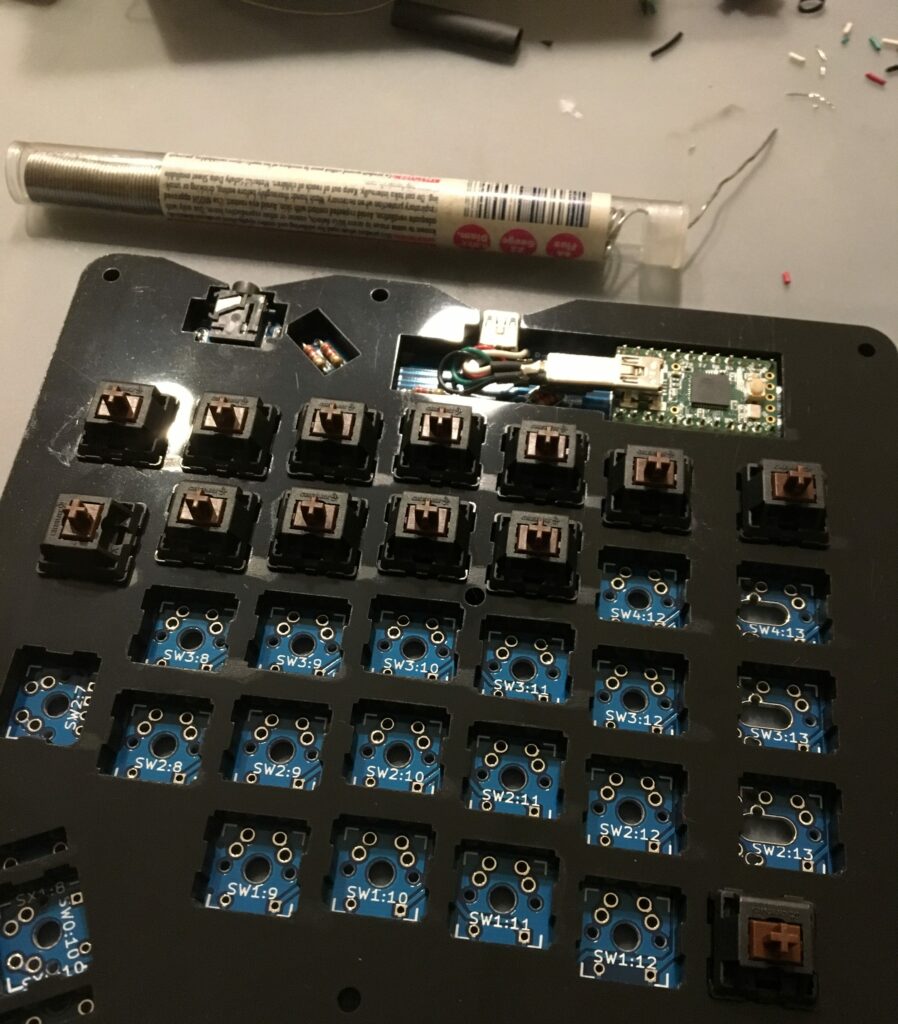

I purchased the pcbs and electronics kit from Profet Keyboards, switches from mechanicalkeyboards.com, and keycaps from pimpmykeyboard.com and assembled an ErgoDox keyboard. I had never soldered surface mount components before and it was a bit of an adventure learning how to effectively solder the small diodes.

Soldering the larger components and switches was a piece of cake after that!

The default case option for the ErgoDox is a laser cut case and switch plate, so I turned, of course, to the Glowforge. I ordered some 5mm Delrin from McMaster Carr as a stiffer alternative to the recommended 5mm acrylic. The Delrin was pretty tough, requiring two passes at 145 speed/full power to cut cleanly through. I cut the layers below the plate from 3mm clear black proofgrade acrylic and I’m testing both Maple and Cherry as top layers. So far I like the Cherry but I may also try walnut and/or read oak before making a final decision.

Once I decide on a wood species, I want to pick up an unfinished board large enough to cut the whole face plate and finish it with a less glossy finish.